DPMO stands for “Defects Per Million Opportunities,” a key term in quality control. It measures how many defects occur in a process out of one million chances. This helps companies understand their product quality. By tracking DPMO, they can find problems early and improve efficiency.

In simple terms, DPMO shows how close a process is to perfection. The lower the DPMO, the better the quality of the product or service. It’s often used in Six Sigma and other quality systems. Understanding DPMO helps teams maintain high standards and customer satisfaction.

What Does DPMO Mean in Quality Control?

DPMO stands for “Defects Per Million Opportunities,” a standardized metric used in quality control and Six Sigma methodologies to measure process performance by calculating how many defects would occur if there were one million opportunities for a defect to happen. This metric allows organizations to compare the quality performance of different processes, regardless of their complexity or the number of opportunities for errors, making it a universal benchmark for evaluating manufacturing, service delivery, and business processes.

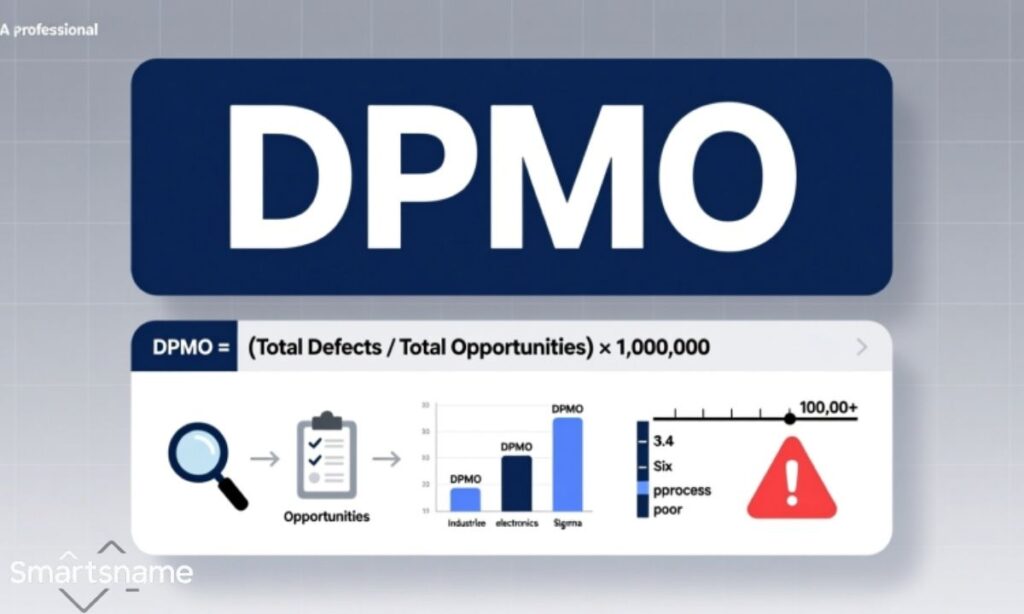

DPMO is calculated by dividing the number of defects by the total number of opportunities, multiplying by one million, and provides a clear picture of process capability and areas needing improvement.

Why Is DPMO Important in Quality Control?

DPMO is important in quality control because it provides a standardized, universal metric that allows organizations to measure, compare, and benchmark process quality across different departments, products, and even industries regardless of complexity or scale.By expressing defects in terms of millions of opportunities, DPMO makes it possible to track incremental improvements with precision, identify specific problem areas that need attention, and demonstrate the tangible impact of quality initiatives to stakeholders, ultimately driving continuous improvement and reducing costs associated with defects, rework, and customer dissatisfaction.

What Does DPMO Stand For?

DPMO stands for “Defects Per Million Opportunities,” a key performance indicator used in Six Sigma and quality management systems to quantify the rate at which defects occur in a process when scaled to one million opportunities for failure.

This acronym represents both a measurement tool and a philosophy of striving for near-perfect quality, where lower DPMO values indicate higher process capability and better overall quality performance, with world-class organizations typically aiming for DPMO rates below 1,000 and Six Sigma certification requiring achievement of 3.4 DPMO or less.

What Does DPMO Mean in Text?

In text or online slang, DPMO often means “Don’t Piss Me Off.”

It’s used to show anger or frustration in a casual way.

What Is the Origin of the DPMO Slang Term?

The slang DPMO became popular through songs and social media.

It’s often used by younger audiences to express strong emotions.

Is DPMO a Good or Bad Thing?

DPMO isn’t always bad—it depends on the tone and situation.

It’s mostly used jokingly, but can sound rude if taken seriously.

DPMO vs. Other Quality Metrics

- DPMO vs. Defects Per Unit (DPU) – DPMO normalizes to one million opportunities while DPU simply counts defects per item without standardization for comparison

- DPMO vs. First Pass Yield (FPY) – FPY measures percentage of units passing without rework while DPMO quantifies defect rate per million opportunities providing granular detail

- DPMO vs. Parts Per Million (PPM) – PPM counts defective units per million while DPMO counts individual defects per million opportunities allowing multiple defect tracking

- DPMO vs. Sigma Level – Sigma level converts DPMO into standard deviation units from mean providing statistical confidence while DPMO gives absolute defect count

- DPMO vs. Cost of Poor Quality (COPQ) – COPQ monetizes quality failures in dollars while DPMO quantifies defect frequency without financial impact assessment

- DPMO vs. Overall Equipment Effectiveness (OEE) – OEE combines availability, performance, and quality into single metric while DPMO focuses exclusively on defect opportunities

- DPMO vs. Rolled Throughput Yield (RTY) – RTY multiplies yields across process steps showing cumulative success while DPMO isolates defect rate at opportunity level

- DPMO vs. Process Capability Index (Cpk) – Cpk measures process centering and variation against specifications while DPMO counts actual observed defect occurrences

- DPMO vs. Scrap Rate – Scrap rate measures unusable material percentage while DPMO tracks defects regardless of whether product is salvageable or scrapped

- DPMO vs. Rework Rate – Rework percentage shows items requiring correction while DPMO captures all defects including those fixed and unfixable failures

- DPMO vs. Customer Complaint Rate – Complaint rate tracks external customer-reported issues while DPMO measures internal process defects before customer receipt

- DPMO vs. Warranty Claims – Warranty metrics track post-sale failures while DPMO monitors manufacturing quality before product shipment and customer use

- DPMO vs. Mean Time Between Failures (MTBF) – MTBF measures reliability over time while DPMO assesses initial production quality at moment of manufacture

- DPMO vs. Defect Density – Defect density measures defects per unit area or code lines while DPMO standardizes across opportunities regardless of size

- DPMO vs. Quality Score – Composite quality scores combine multiple factors while DPMO provides single focused metric on defect opportunity rate

- DPMO vs. Net Promoter Score (NPS) – NPS measures customer loyalty and satisfaction perception while DPMO objectively quantifies production defect rates

- DPMO vs. Audit Findings – Audit results identify compliance gaps while DPMO continuously measures process output defect performance quantitatively

- DPMO vs. Right First Time (RFT) – RFT percentage shows items correct initially while DPMO quantifies defects per million allowing deeper granularity

- DPMO vs. Supplier Quality Rating – Supplier ratings aggregate multiple performance factors while DPMO specifically measures incoming material defect opportunities

- DPMO vs. Inspection Pass Rate – Pass rate shows percentage accepted while DPMO normalizes failures across opportunities for better trending and comparison

- DPMO vs. Zero Defects Goal – Zero defects is aspirational target while DPMO provides measurable progress metric toward that ultimate quality objective

- DPMO vs. Quality Index – Composite indices weight various quality aspects while DPMO maintains singular focus on defect opportunities for clarity

- DPMO vs. Downtime Percentage – Downtime measures unavailability while DPMO assesses quality of output during operational periods without availability consideration

- DPMO vs. Cycle Time – Cycle time measures process speed while DPMO evaluates quality regardless of production velocity or throughput rate

- DPMO vs. Throughput Rate – Throughput quantifies volume produced while DPMO measures quality of that output independent of production quantity

- DPMO vs. Control Chart Violations – Control charts identify statistical process instability while DPMO counts actual defects regardless of variation patterns

- DPMO vs. Gage R&R – Measurement system analysis validates inspection reliability while DPMO assumes measurement accuracy and counts observed defects

- DPMO vs. Design for Six Sigma (DFSS) – DFSS prevents defects through upfront design while DPMO measures actual defects in existing process output

- DPMO vs. Total Quality Management (TQM) – TQM represents comprehensive quality philosophy while DPMO serves as specific quantitative measurement tool within TQM

- DPMO vs. ISO 9001 Compliance – ISO certification proves quality system existence while DPMO measures actual process performance results numerically

Real-World Applications of DPMO

- Automotive Manufacturing Assembly Lines – Tracking defects per million opportunities across thousands of components ensures vehicles meet safety and quality standards consistently

- Pharmaceutical Drug Production – Monitoring DPMO in tablet coating, dosage accuracy, and packaging prevents life-threatening medication errors reaching patients

- Semiconductor Chip Fabrication – Measuring defects per million on microscopic circuit features where single failure renders entire expensive chip unusable

- Commercial Aviation Maintenance – Tracking maintenance procedure defects per million steps prevents catastrophic in-flight failures and ensures passenger safety

- Medical Device Manufacturing – Monitoring pacemaker, surgical instrument, and diagnostic equipment DPMO ensures life-critical devices function perfectly when needed

- Food Processing and Packaging – Measuring contamination, weight variance, and seal defects per million prevents consumer health risks and brand damage

- Call Center Customer Service – Tracking error rates per million customer interactions identifies training needs and improves satisfaction through defect reduction

- Software Development Code Quality – Measuring bugs per million lines of code or user stories identifies problematic modules requiring refactoring attention

- Banking Transaction Processing – Monitoring errors per million transactions prevents financial losses, regulatory penalties, and customer trust erosion

Frequently Asked Question

What is the DPMO meaning in quality control?

DPMO means “Defects Per Million Opportunities,” used to measure process quality and errors.

What does DPMO stand for in business?

In business, DPMO stands for “Defects Per Million Opportunities,” showing how often mistakes occur.

What is the simple meaning of DPMO?

DPMO means how many defects happen per one million chances of error.

What is DPMO meaning in Six Sigma?

In Six Sigma, DPMO measures the number of defects per million opportunities to check process performance.

How is DPMO meaning used in manufacturing?

It shows the accuracy of production by counting defects per million product opportunities.

What does a high DPMO mean?

A high DPMO means the process has more defects and lower quality.

What does a low DPMO mean?

A low DPMO means the process has fewer defects and better quality.

Why is DPMO important?

DPMO helps identify errors and improve the quality of products or services.

How do you calculate DPMO?

You calculate DPMO by dividing defects by total opportunities, then multiplying by one million.

What is an example of DPMO?

If a process makes 3 defects in 1,000 opportunities, the DPMO is 3,000.

Conclusion

DPMO is an important tool for understanding quality and performance in any process. It helps businesses find mistakes and improve their products or services. By checking DPMO, companies can work towards fewer defects and better results. It’s a simple but powerful way to measure success.

In quality control, DPMO stands for more than just numbers—it shows how well a process runs. A lower DPMO means higher quality and greater customer satisfaction. Tracking it regularly helps maintain strong standards. This makes DPMO a key part of achieving excellence in any industry.

Tariq is a dedicated blogger with 4 years of experience in the field of name-related blogs. Over the years, he has researched and written extensively about baby names, business names, and creative ideas that inspire identity and uniqueness. His content has helped readers across the globe discover meaningful and memorable names.

Currently, Tariq is working on SmartsName.com, where he continues to share his passion for names. With his knowledge and expertise, he aims to provide readers with unique, creative, and valuable suggestions that make the journey of choosing the perfect name easier and more enjoyable.